How To Sevice A Table Fan

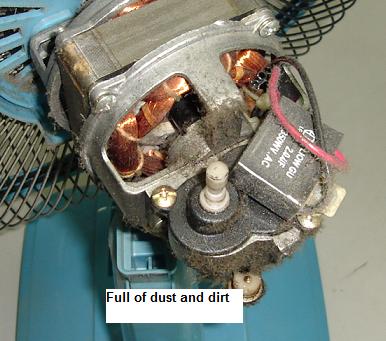

This Hestar table fan problem was not rotating even if it already switched “On”. You could hear a sound coming from the motor and when I try turning the propeller (plastic blade) I found it to be stuck! By right a good fan when you turn it, the propeller should rotate according to the force applied on it. It could be the long time of accumulation of dust that had jammed the motor shaft preventing it from turning smoothly.

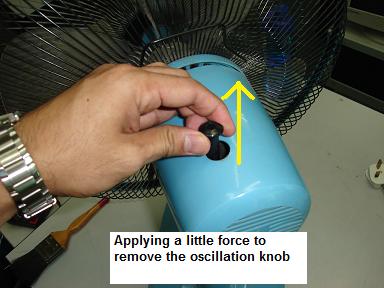

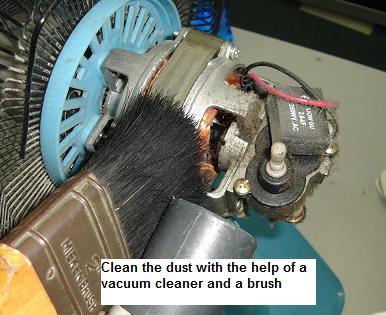

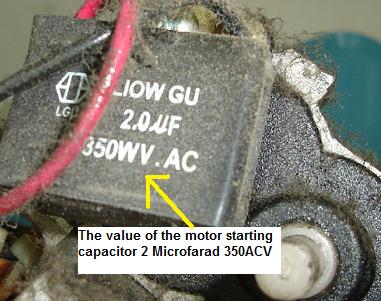

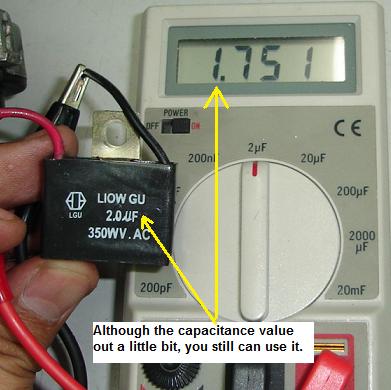

Once the back cover (motor housing) and the oscillation knob have been removed, I could see lots of dust and dirt around the motor. I used a vacuum cleaner together with a brush to clean up the dust. You could also see a motor starting capacitor ( 2 microfarad 350 VAC ) attached beside the motor. This is the Metallized Polypropylene Film type of capacitor.

Anyway I took out the capacitor and check it with a digital capacitance meter to see if the capacitance is within range or not. The value was 1.751 microfarad, and it is slightly lower then the tolerance (the tolerance for this type of capacitor is about 10%). If the capacitance value is too low then I will replace it with a new one. Please make sure you get a replacement with the same or higher voltage and if possible with the same capacitance. You can easily get a motor starting capacitor from any electronic distributors. I put back the motor starting capacitor and start servicing the fan.\

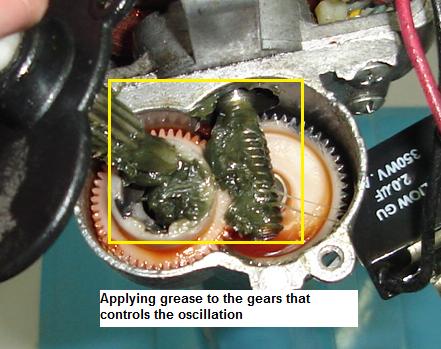

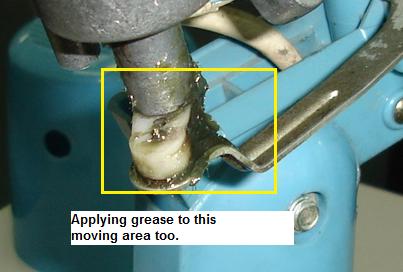

First I sprayed the Philip oil base to the contact that caused the shaft hard to rotate. The motor shaft immediately rotates (turned by my hand) smoothly the moment it had oil in it. When I switch the fan “On” again, the motor start to run! I switch off the fan again and applied some grease into the back gear (oscillation knob gears) that controls the fan whether you want it to be “still” or “oscillate” (don’t use the oil spray in this area because it can worn out the gear faster).

After everything was done, I tested the fan and it worked like a new fan! Servicing the table fan is not difficult and you can try servicing one in your home. Remember, safety have to come first, make sure you unplug the AC cable before starting to dismantle the fan apart.

Learn How You Can Become A Professional In Testing Electronic Components

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved