|

How To Completely Tackle Intermittent Fault In Electronic Circuits

For those who already got my ebook on Testing Electronic Components you would have downloaded the free bonus report on “How to Easily Repair Intermittent Problems in Electronic Circuits”. You might find this article have some similarity to the free bonus but in this article I will explain more in depth on how to successfully locate intermittent problems in any electronic circuits.

The word “Intermittent” in electronics repair means sometimes the equipment will work and sometimes not. Intermittent problems can happen in any equipment and in any circuits. When you want to see the fault of the equipment (for example, color missing in TV) the equipment works just fine throughout the day without problem and it can last for many days and you do not have the chance to see the fault. However, sometimes the problem (color missing) just ‘pop” up for couple of seconds and then back to normal again.

Well, the problem can be dry joints, broken tracks, loose connection at the cable area, bad components and etc. These are the faults that had caused many electronic repairers got frustrated and if you do not have a better way to solve these kinds of problems, you may be losing out your precious time in troubleshooting. Our aim as electronics repairer is to try to solve an electronic problem as fast as we could so that the extra time that we have will be used to repair some other equipment. If you spend the whole day trying to locate the intermittent fault, which means you will repair less machine in a day and obviously earn less. I hope this article in some way may help you to find out intermittent fault fast and have time for other equipment and eventually make more money in a day.

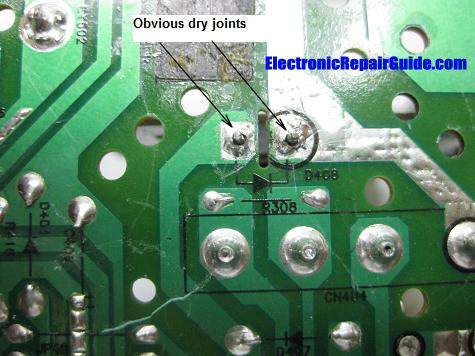

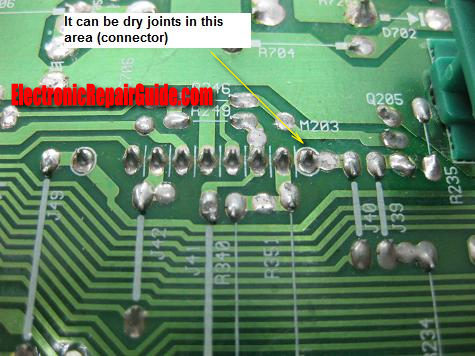

Dry joints and Cable Loose Connection,

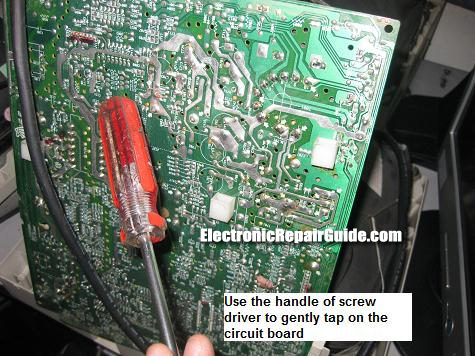

These two faults can be easily detected with the help from our eyes and from the handle of screw driver. Scan the board first for any bad contact of the solder joints in the components’ lead. Some are very obvious and some have tiny cracks around the solder pad. If you can’t see any dry joints then you may need to power On the equipment and gently knock the equipment (or suspected area) with the handle of a screw driver as seen in the photo.

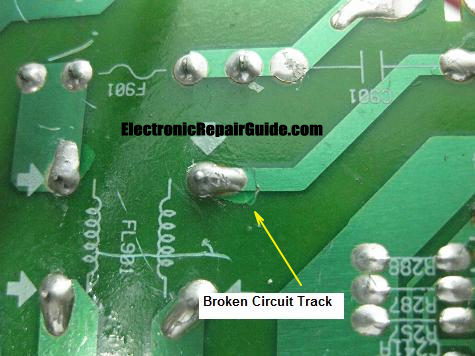

Circuit Track Broken,

Usually, the circuit line/track

will not break by itself but because of some cheap material used to fabricate the board, yes, the circuit line

may break if some force was put upon the board. For example, the CRT Monitor base/stand could cause the board to

break because the board was so thin and it can’t stand the amount of pressure from above (which is the Monitor

weight itself). Different manufacturers manufacture different type of circuit boards and from my experience, a thicker board will have less problem

then a thin board in term of the reliability of the circuit track.

In order to locate this problem, you may need a magnifying glass to see the broken track. It can be a tiny crack or very obvious crack. You may also use the handle of the screw driver to gently knock on the suspect area and hope that you could see the problem.

Decayed glue

Decayed glue can conduct electricity and because of this, it has the ability to create intermittent problem in electronic circuit by shorting out the components that were located near to the decayed glue. For your information, I have seen decayed glue located underneath the power transformer. You just can’t see the decayed glue from above and it took me many hours to solve the intermittent problem in power supply.

Every time when I see decayed glue around electronic components, I would use a test pen to scrap it off and clean it with Thinner.

Coke, Coffee, Water from Air condition

The users accidentally caused the coffee or coke splashed onto the electronic circuit. Do you know that the acidic drinks could cause a complete failure in electronic circuit besides intermittent faults? Complete failure means, the acid had eaten up the components lead and even though you can clean the board with the help of Thinner and etc, somehow the circuit will be unstable and causing lots of problem which includes intermittent faults.

If the customer equipment had Air condition water inside and the customer had delayed in sending the equipment for repair, the leads of the components can become rusted and we will have a hard time to fix this kind of problem.

If the damaged was not big enough, you can proceed to clean the board and repair the equipment and “hopefully” it will last and if there are too many components been affected I suggest that you return the set back to customer as a repeat call for repair will surely put off your profit.

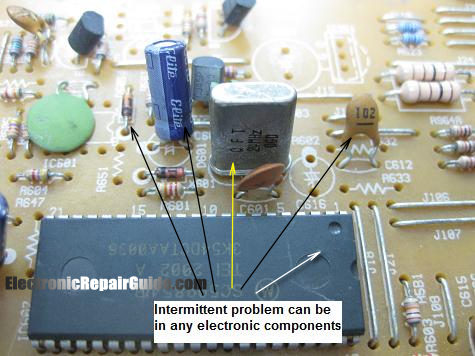

Intermittent Components Problem

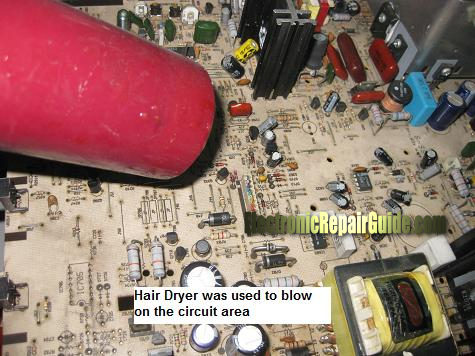

Any components from Relays, Semiconductors, Capacitors to Crystals can cause intermittent problem in electronic circuit. It can cause your equipment to fully malfunction or sometimes work and sometimes don’t. In certain problems, you can quickly use a hair dryer to force the problem to appear and then use a Freezer (coolant) to cool it down and see which components react to the Freezer. Generally the component that reacts to the Freezer is the one that have problem.

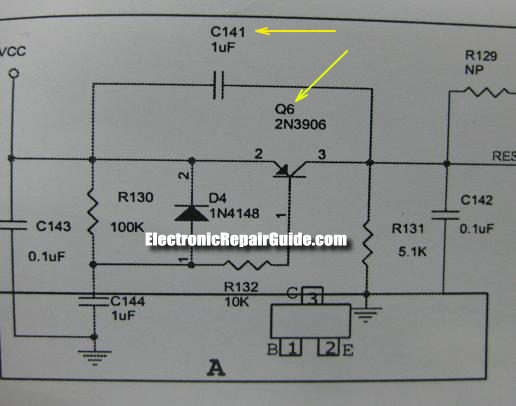

From experience, it is not always the case. Sometimes a component that is corresponding to the component that reacts to the Freezer is the cause. From the schematic below, the C141 is the cause of the intermittent problem and not Q6 although the FREEZER was sprayed onto Q6. Please take note of this.

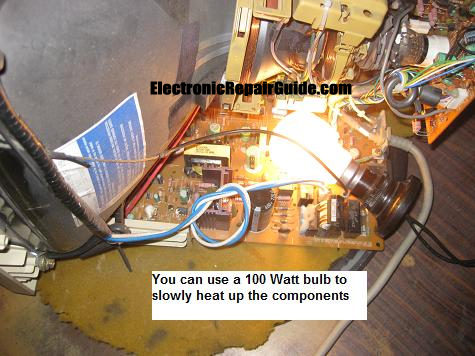

In some cases, you can use a 100 watt bulb to slowly apply the heat to the electronic circuit and hope that the intermittent problem will surface. You can also use a Hair dryer and wrap the front blower part with aluminium foil to make the hot air focus on few components instead of a large area. With this you can narrow down your search of the intermittent component.

Bad Electronic Components

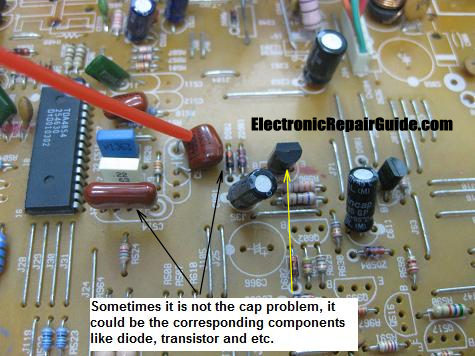

Please do not think that when every times there is an intermittent problem, the cause must be an intermittent component problem, dry joints, decayed glue and etc. It can be a solid bad component too. An open start up resistor in switch mode power supply can cause sometimes have power and sometimes no power. I came across too that an open resistor in the standby circuit in Monitor can cause intermittent no power!

Conclusion- Although I could not cover all the intermittent causes and solutions in this article, the explanation that I have given above are good enough to solve most of the intermittent problems in electronic circuit. I suggest that you analyse your type of circuit well (equipment that you repair in your industry) so that whenever there is any intermittent problem you will know where to begin to check. That’s all for this month repair article and hope you will enjoy this article. Take care and have a brilliant day ahead!

Click here to learn how you can become a Professional in Testing Electronic Components

Click here to learn how you can become a Professional in LCD Monitor Repair

Recommendation:

Recommended Mr Kent Projection Television Repair Membership website-Visit Now!

Recommended Mr Kent LCD TV Repair Membership website-Visit Now!

Recommended Mr Kent Plasma TV Repair Membership website-Visit Now!

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved