|

How To Completely Check The High Voltage Circuit In CRT Monitor/Television

Many electronic repair technicians have problem in identifying fault in the high voltage section (Flyback Tansformer). Whenever a CRT Monitor or Television has the complaint of no high voltage, the first thing they suspect was a bad flyback transformer. For your information, no high voltage symptoms are not necessary must be cause by a bad Flyback, in fact there are other possible causes that contributes to the no high voltage problem. In order for a Flyback transformer circuit to functioning well and produce the high voltage, there must be some requirement to be met. Here are the requirements:

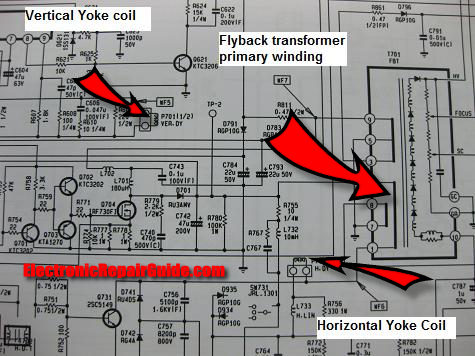

1) B+ voltage- Every flyback transformer primary winding needs this voltage which comes from the switch mode power supply. The B+ voltage for CRT Monitor is about 60 to 80 VDC and for Television is about 110 VDC-it depends on sizes and model of the equipment too. If this voltage missing due to problem in SMPS or from the B+ voltage circuits itself then there will be no high voltage even though other components/signals are working fine. This is the first point that you need to check if there is no high voltage but have power in the equipment.

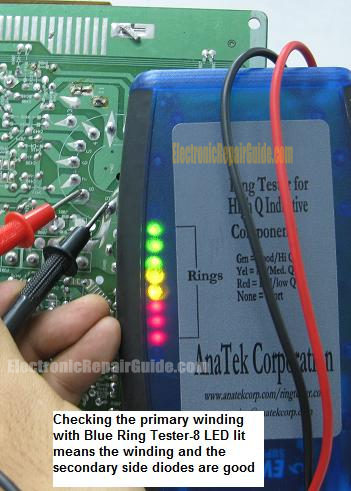

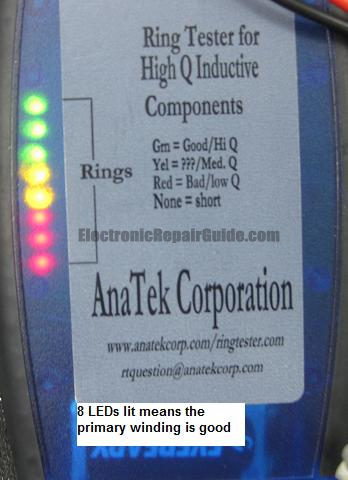

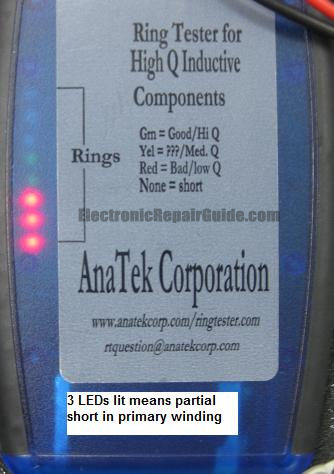

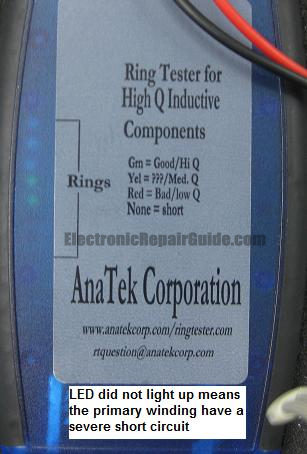

2) The Primary Winding- Lots of electronic repairers did not know how important the primary winding is. If there is a problem with the primary winding like open circuit (very rare) and shorted winding the SMPS will shutdown or causing the power supply to blink. Many of them check the primary winding using normal ohm meter or even inductance meter. The fact is that you will not get a good result using such meters. You have to use a meter like the Blue Ring Tester which was specially designed to test the primary winding of the flyback transformer. If you did not check this winding or using the wrong way to test the winding, you will end up not successful in finding the fault. If you haven’t invested in this meter then I strongly recommend you to get one soon to speed up your repair work.

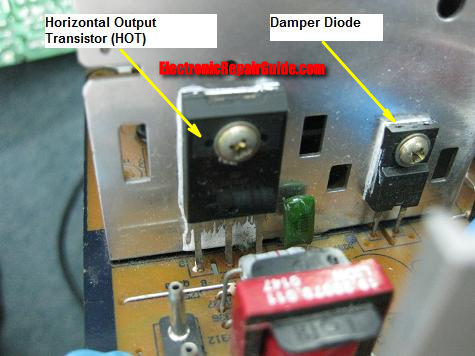

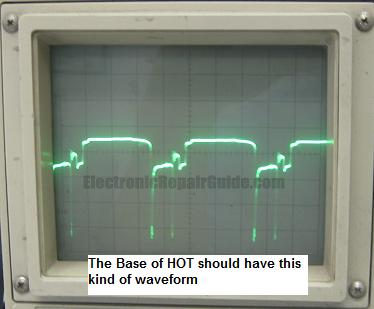

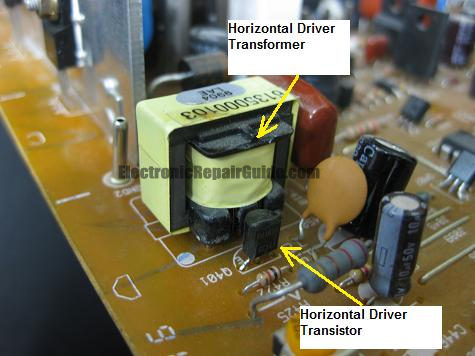

3) Horizontal Drive Signal- Even though you have a good primary winding and good B+ voltage, if there is no horizontal drive signal the flyback will not be energized! This horizontal drive signal/waveform comes from the horizontal/vertical oscillator IC and to the base pin of Horizontal Output Transistor (HOT) after went through the horizontal driver transistor and the horizontal driver transformer.

A missing horizontal drive signal will not turn on the HOT thus there will be no switching from the HOT and the primary winding will not function. The best test for this signal is to use an oscilloscope and you could see this signal/waveform from the photo below.

For your information if there is improper waveform to the HOT, it will cause the HOT to burn after sometimes. So make sure the H/V oscillator IC is producing a good output drive waveform.

4) The Flyback Transformer Internal Capacitor- This internal capacitor causing lots of problem in CRT Monitors. The symptoms can be shutdown upon turn on, have tic-tic sound, power blink, no high voltage, causing low B+ voltage, shorting the HOT immediately or after sometime, blow the SMPS section and many more. Make sure the internal capacitor have the value of 2.7 nano farad to about 4.5 nano farad when test with digital capacitance meter measuring from the anode cap to ground. You also need to test the internal capacitor using your analog meter set to X 10 K ohm as sometimes the internal capacitor can be tested good using digital capacitance meter but fail when test with analog meter. If you got any steady reading from the analog meter then this has proven the internal capacitor has shorted.

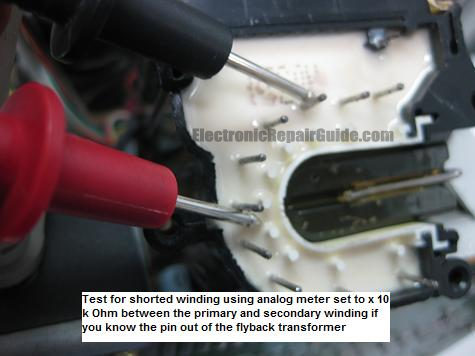

5) The Primary and Secondary Winding- Although it was rare to find shorted winding between the primary and the secondary, it is a good practice just to make sure that both windings did not short together thus causing problem to the equipment. Set your analog meter to x 10 k ohm and place any probes (red or black) on the primary and secondary winding. If there is continuity then you can confirm that it has shorted internally.

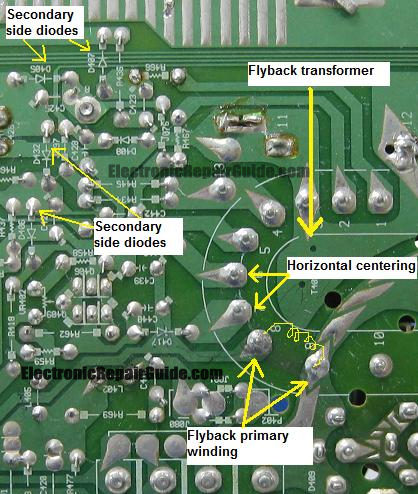

6) Secondary side components- If there is a primary winding obviously there must be secondary winding. The secondary side could consist of few secondary windings. The windings are for the G1 voltage, heater voltage (for filament in TV tube), supply voltage to other circuits, ABL (Automatic Blanking Limiter), X ray protection feedback, AFC (Automatic Frequency Control) and etc. If there are components like resistors open circuit in the secondary side, high voltage could still be produce but is just that the display may become too dark or too bright. However if there is any components shorted like diode and capacitor, it would cause the SMPS to blink and no high voltage.

There is a fast way to test if all the secondary side diode is good or bad. Just place your Blue Ring tester onto the primary winding pins. If there is a full LED lit from the tester then the secondary side diodes are good. If the LED goes off then this suggest it could be fault in the primary winding (shorted), shorted HOT or shorted in one of the secondary diode. Since the LED from the tester did not lit, your next step would be to remove the flyback and retest it again. If off board the tester still shows no LED light then you can confirm the flyback transformer has developed a shorted primary winding. If off board the tester shows full LED light then it is confirm the Flyback transformer is okay and the cause can be either a bad HOT or shorted secondary side diode. Use your ohmmeter to test on the HOT and the secondary side diode.

7) Shorted Picture Tube- I have seen some shorted pc tube that prevents the high voltage from being energized. That means, once I pull out the anode cap from the tube there is high voltage. Once I put the anode cap back to the tube and power “On”, there was no high voltage at all. Replacing the pc tube solved the no high voltage symptom. Although it was rare, it did happen!

Conclusion- Carefully study and practice the steps above until you are familiar with this circuit and testing and I’m very sure you will have the confident in tackling no high voltage symptom in any CRT Monitor/Television. If you have checked all of the steps given above and still could not find out the fault then most probably the cause of the problem is Flyback transformer breakdown when under full load. I have seen this problem before and a replacement of a good flyback transformer solved the no high voltage problem.

If you read it carefully again, in fact these steps of troubleshooting can be apply in repairing SMPS, Inverter and other electronic circuits. Have a fantastic days!

Click here to learn how you can become a Professional in Testing Electronic Components

Click here to learn how you can become a Professional in LCD Monitor Repair

Recommendation:

Recommended Mr Kent LCD TV Repair Membership website-Visit Now!

Recommended Mr Kent Plasma TV Repair Membership website-Visit Now!

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved