|

10 Mistakes That Every Electronic Repairers Should Avoid

If you are in the electronic repairing field, I guess there is some important information that you should and need to know. The information that I’m going to share to you is about the mistakes that many electronic repairers have ignored and never put into practice. These mistakes sometimes can be fatal and you need to take extra precaution when dealing with it. Here are the mistakes:

Electrocution

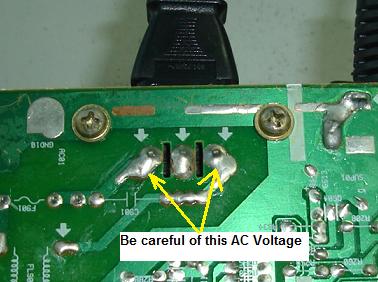

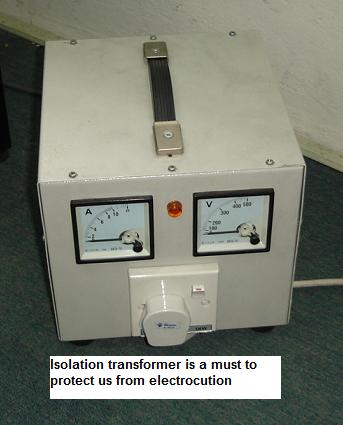

For those seasoned electronic repairers you may find this topic as “easy to handle” due to you already exposed to it every single day. That means you already knew all the consequences of when someone got electrocuted. You will take extra careful when dealing with AC supply and know what to do when performing the voltage test on board. Now for those newbie’s that has just joined this field, I highly recommend you to get an isolation transformer in order to protect yourself from electrocution just in case if anything bad incident happen. I remembered one bad incident happen 10 over years ago where my left hand was slightly burnt due to my hand accidentally touched on the live AC supply. Back then I’ve never heard of what is isolation transformer and my college never emphasis on this subject. I don’t want you to be like me fall into the same bad incident! Treat every AC supply carefully and if you don’t understand, you can always get a repair friend to help you out.

Isolation transformer offer 100% isolation from the AC input line. Even if you are a seasoned electronic repairer, I suggest you to get one too. The isolation transformer shown in the photo has a rating of 1KVA which is equivalent to about 600 Watt and it is a customized isolation transformer. You can easily get a ready made one from your local electronic distributor. For more information about isolation transformer, you can always check from the internet.

Capacitor Discharge

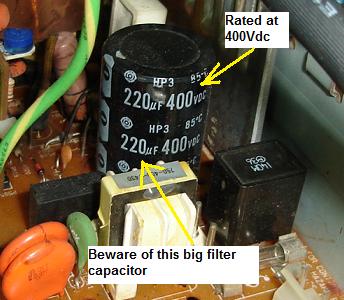

This big filter capacitor (usually rated at 100 uf to 470 uf with 400 to 450 working voltage) in the primary side of power supply is also a potential hazard to electronic repairers. I myself had been discharged by this capacitor before and it really hurt. The mistake that I made was in my mind says that “the voltage will discharge by itself”. Yes it is true only to certain designs and in some designs even though you already switched off the power supply; the charge was still remain in the capacitor. If the start up resistors is open circuit the voltage inside the capacitor can’t be discharged and if possible you have to confirm it with a multimeter. If it reads zero or low voltage then only you begin to work in this area. Due to few times that I made the mistake, I’m now more alert about this area. So newbie’s you got to be well prepared when troubleshooting this area.

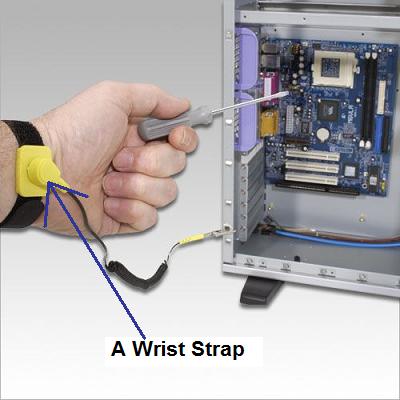

Static Charge A static charge may be built up when two surfaces rub against each other. In our normal activities, we generate static charge all the time. This charge can have a voltage high enough (may be thousands of volts) to create quite a spark. Even though the voltage is high, the current is very low, so only a small amount of power is involved. Static is always a problem when you are repairing and troubleshooting electronic equipment. You must take special precautions whenever you repair any equipment that have CMOS IC’s in it.

Before you touch any parts inside the equipment, always ground yourself to remove of any static charge. Many service technicians and engineers wear a wrist strap which is connected to ground through a one mega ohm resistor. This will safely drains off any static electric charges from their body. Look at the photo and you could clearly see a wrist strap attached to his left hand. If you deal with motherboard repair, hard disk, FET components and etc, it is recommended to get a wrist strap before the static charge kills the electronic components. Tiredness

Take a short nap or rest if you are tired

In doing any repair work one must have the concentration and focus so that the task can be accomplished. If you are tired or weak please take some rest as forcing yourself may invite more problems than you can solve. We as electronic repairers is dealing with electricity and if one mistake (got electrocuted) made we may end up in hospital or even dead. Take a short nap when you are tired. With just 5 to 10 minutes nap, it could refresh your mind and may last you till end of the day. Our mind easily gets tired if we are too concentrating in tackling a problem for a long time. Have a short break and many times during the short break, ideas came and I can easily solve the problem fast.

Transistor/Diode replacement

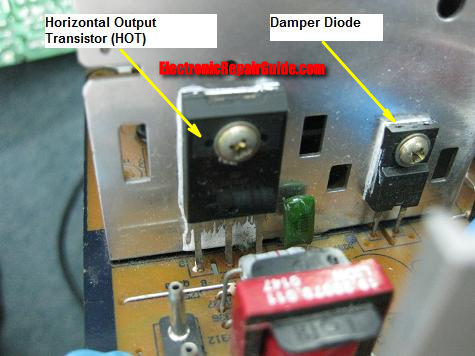

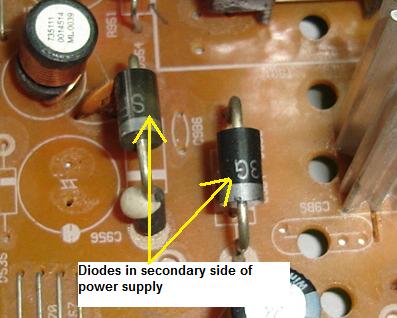

I believe many of you have come across problem where we could not locate original part number for diodes and transistors. Due to this we used the substitution part number hopefully it will work like the original one. The most common components that have substitution part number are transistors and diodes. For you information, you can get easily get the original value from the market for capacitors, resistors, zener diodes and etc. If you are a TV/Monitor repairer, you must have used substitution part number before for the horizontal output transistor (HOT) and for diodes in the secondary output side.

The mistake made by the electronic repairers was not enough time to run the burn in test for the equipment that used the substitution part number. That means, if you don’t properly test the equipment after installing the substitute part, the customer may complaint again after using the set for few days. What you need to do is to fully test the set before sending the equipment back to customer in order to avoid call back.

If you repair a CRT Monitor and you had replaced the HOT with another part number, the best thing to do next is to run the Monitor on all resolution and make sure the HOT temperature is okay and won’t burn your finger when you touch it. If it extremely hot, then you have to be careful as the set may not last long and may come back again for second repair if you insist to send the set back to customer. Try another part number and if possible get back the original part number for longer lasting operation.

Learn How You Can Become A Professional In Testing Electronic Components

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved